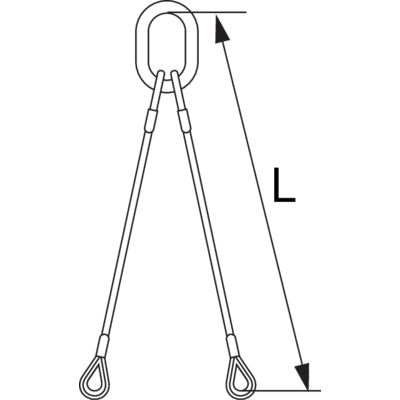

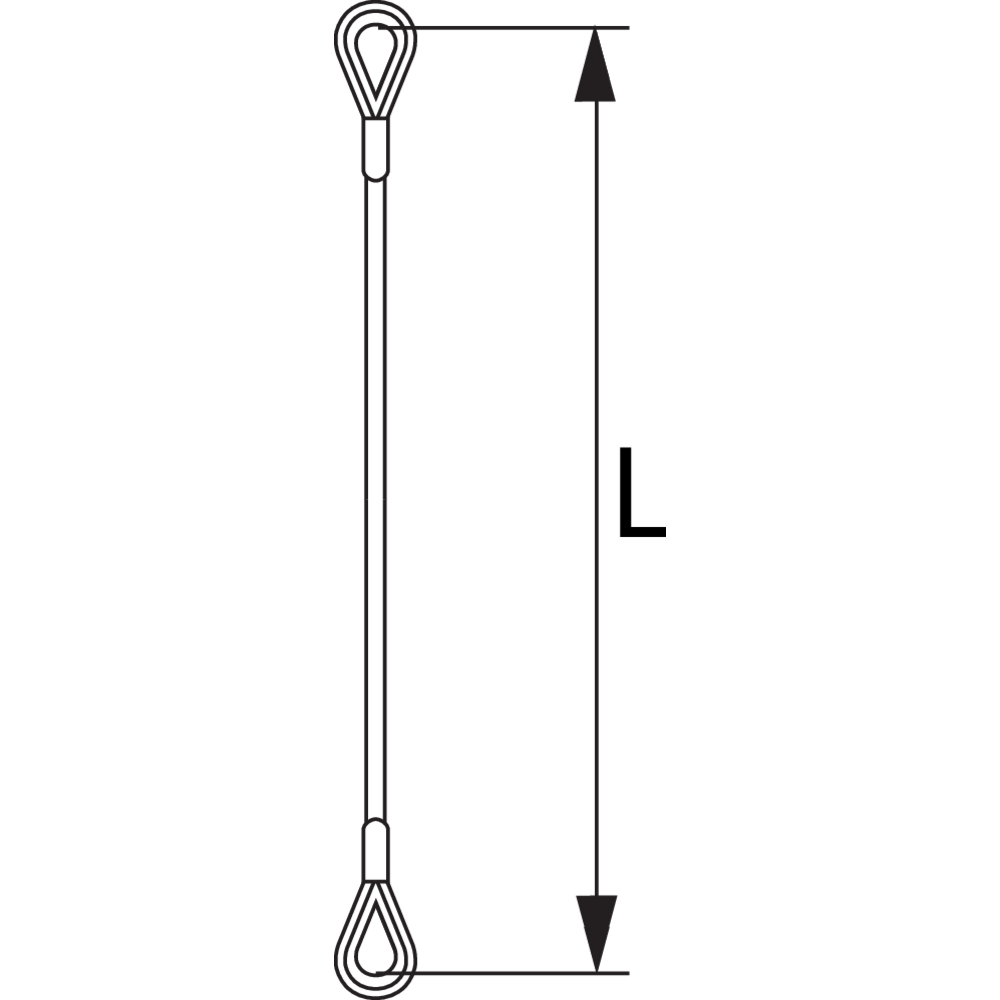

Steel Wire Rope Slings

General

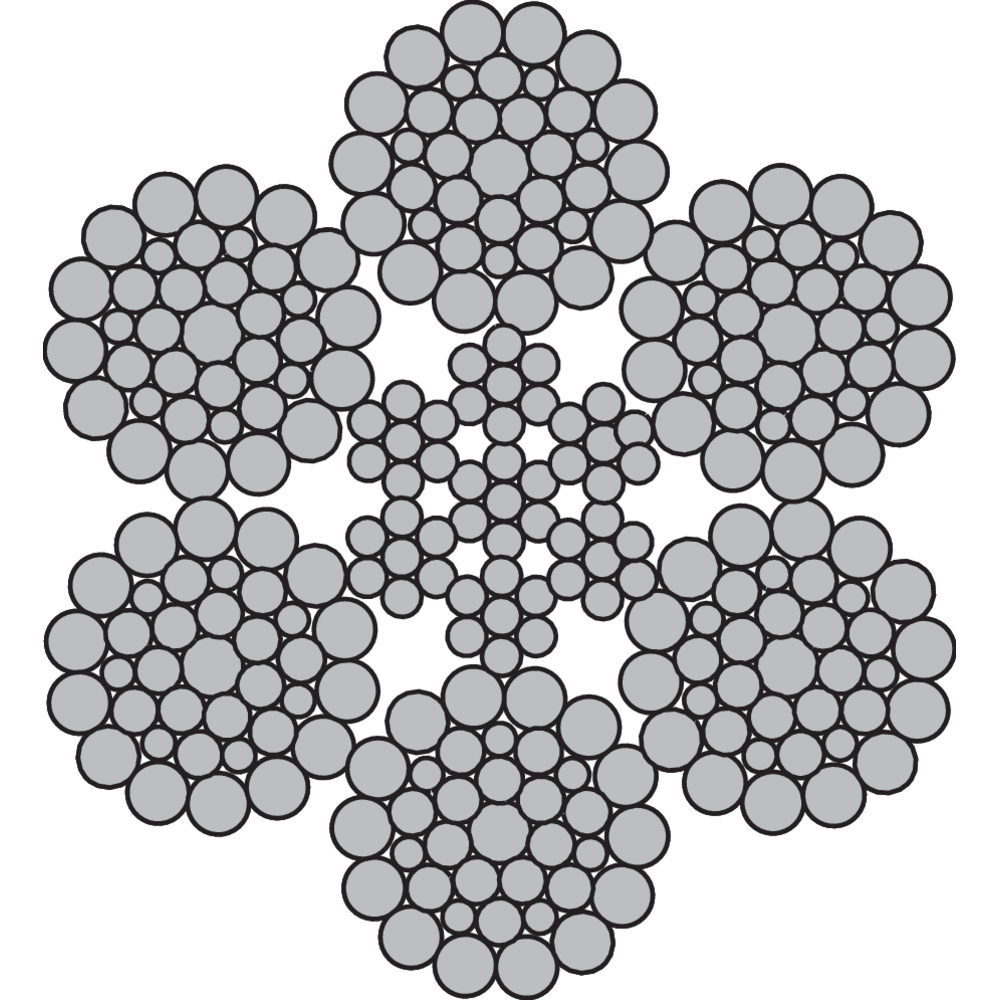

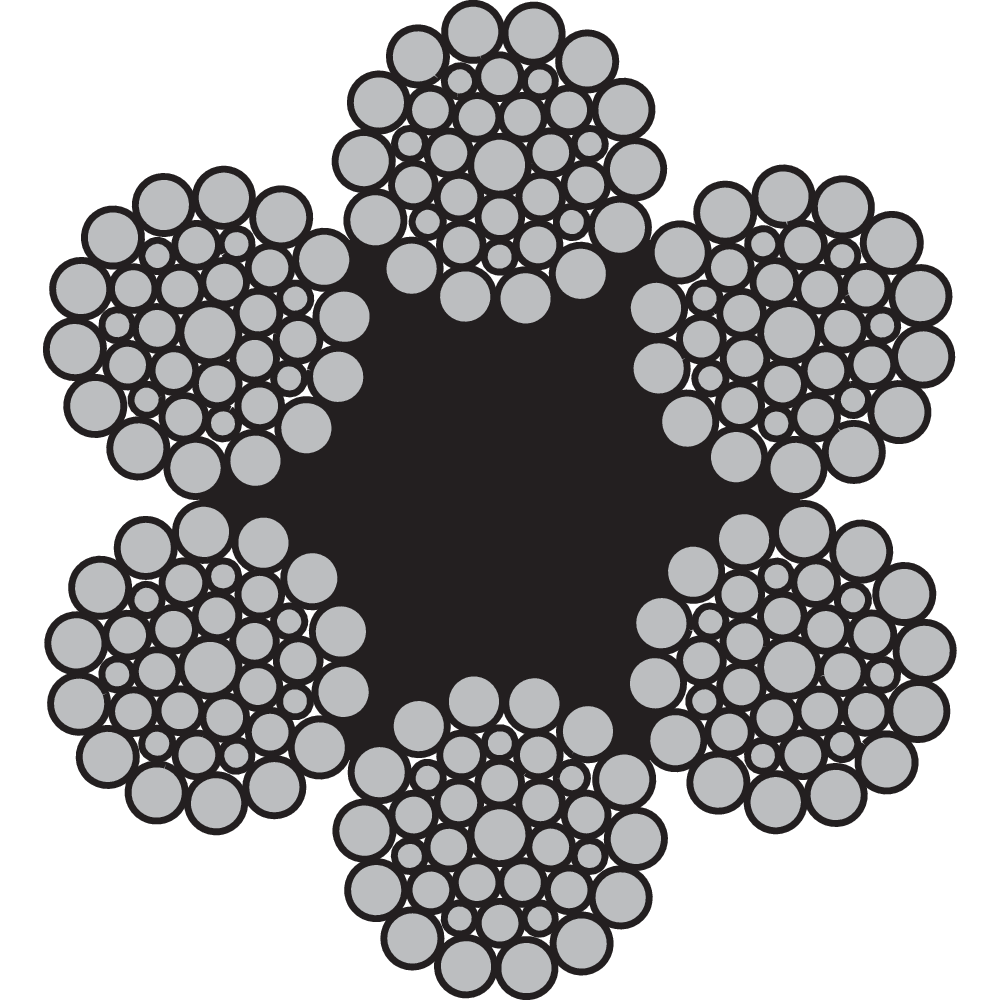

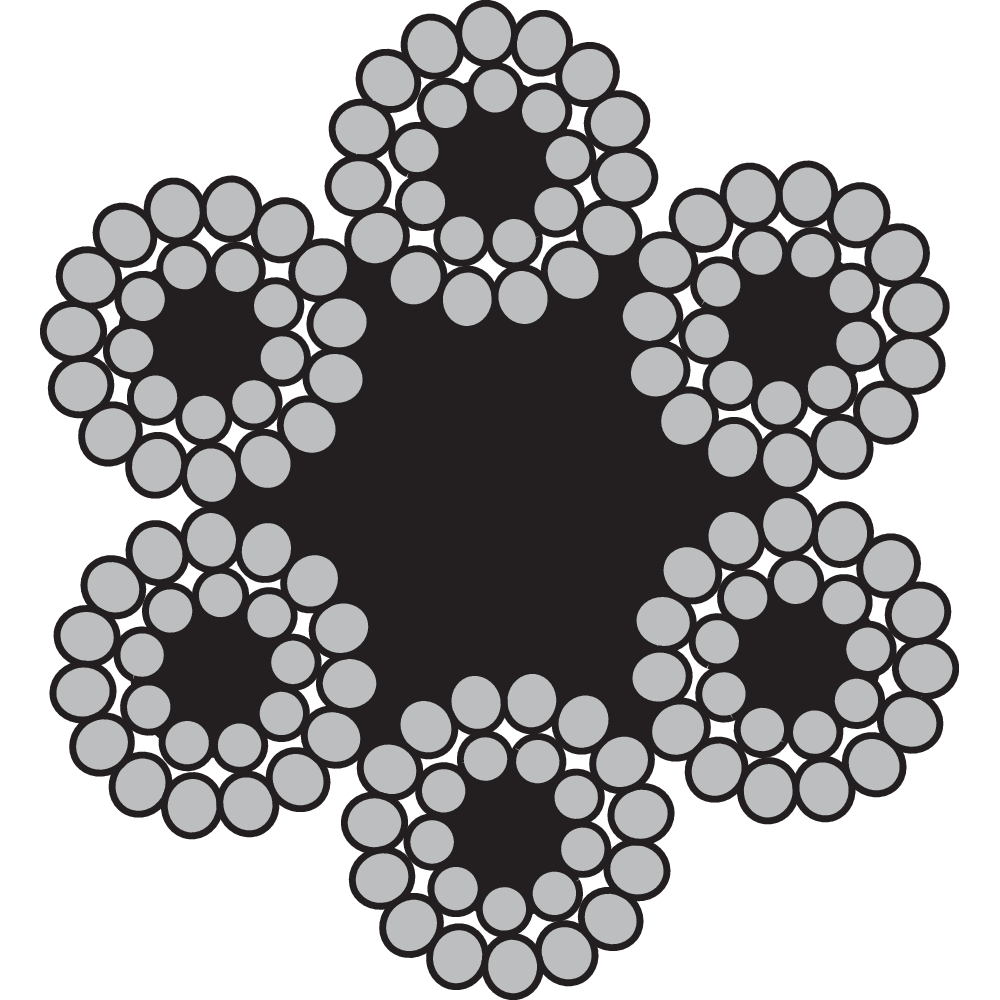

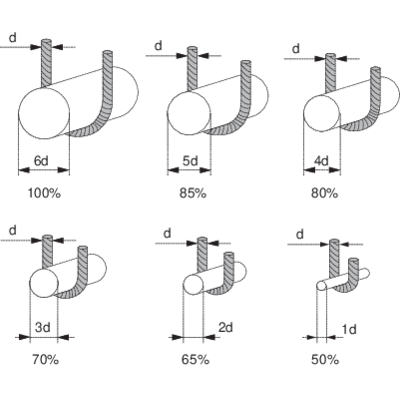

General: Steel wire rope slings are in most cases easier and less expensive than chain slings. Galvanised wire rope provides good protection against corrosion, in extreme environments stainless wire ropes can be used. For extremely heavy lifting wire rope slings are usually the best option.

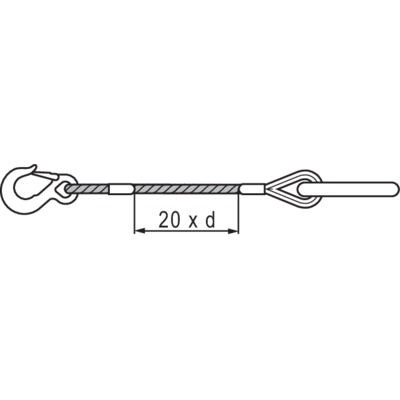

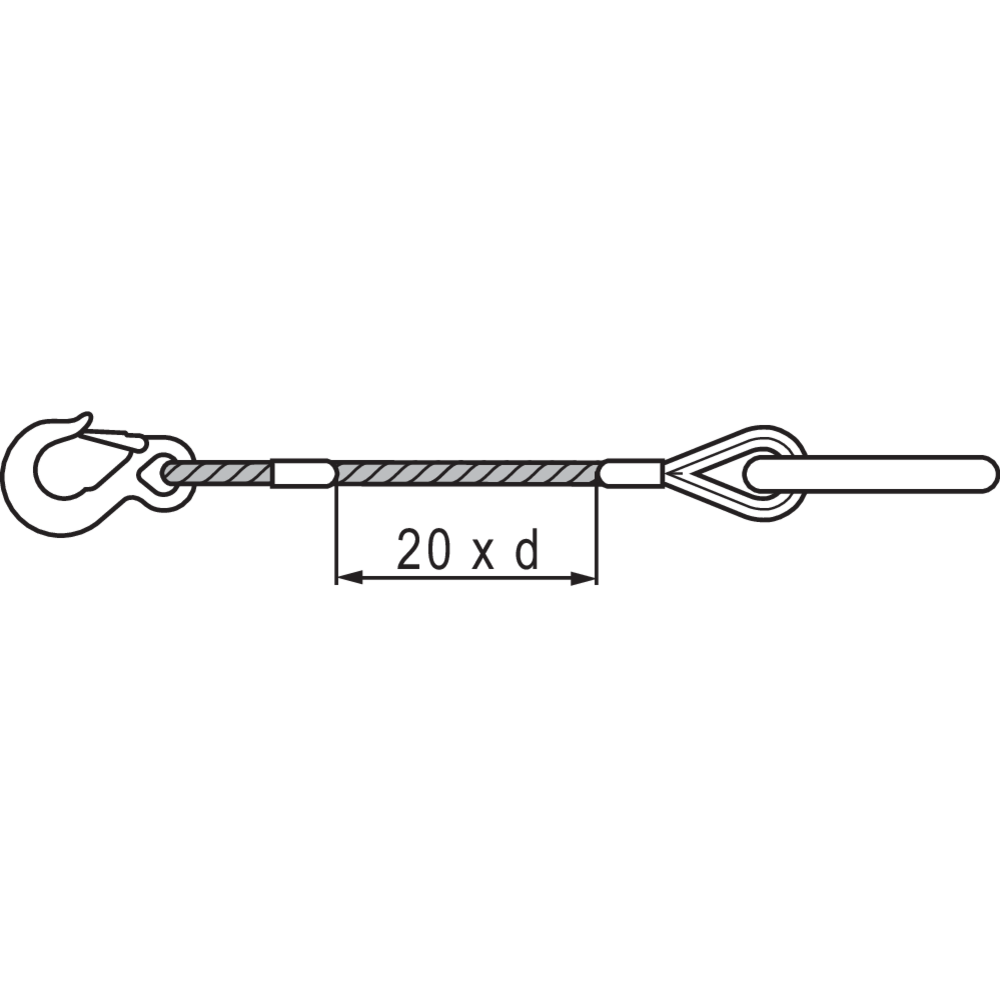

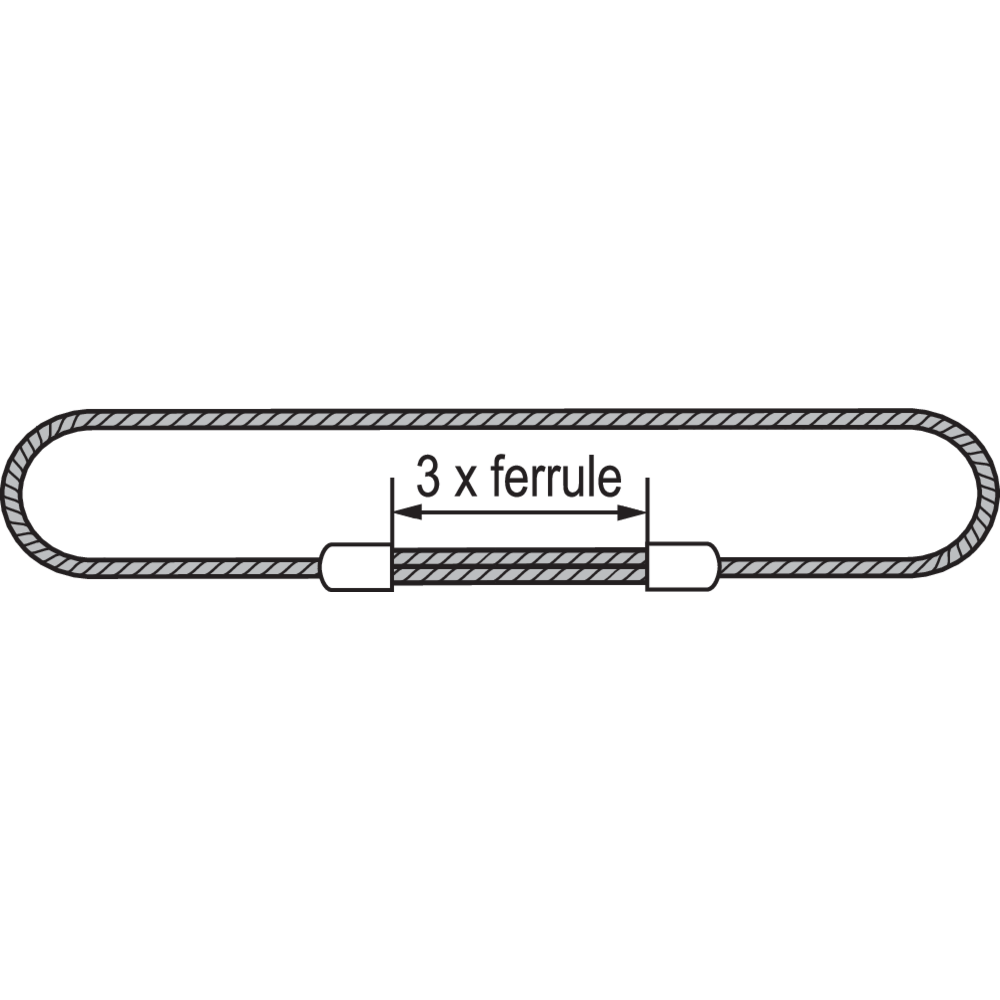

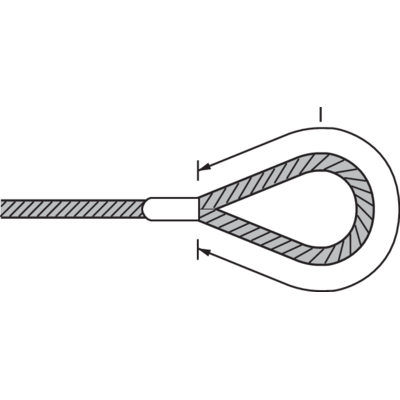

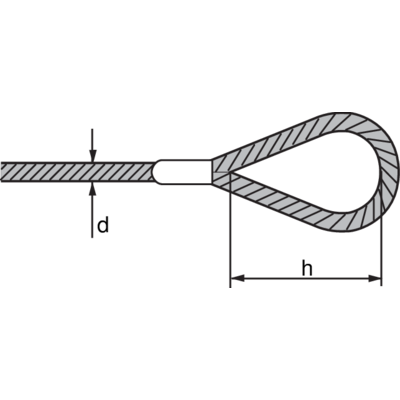

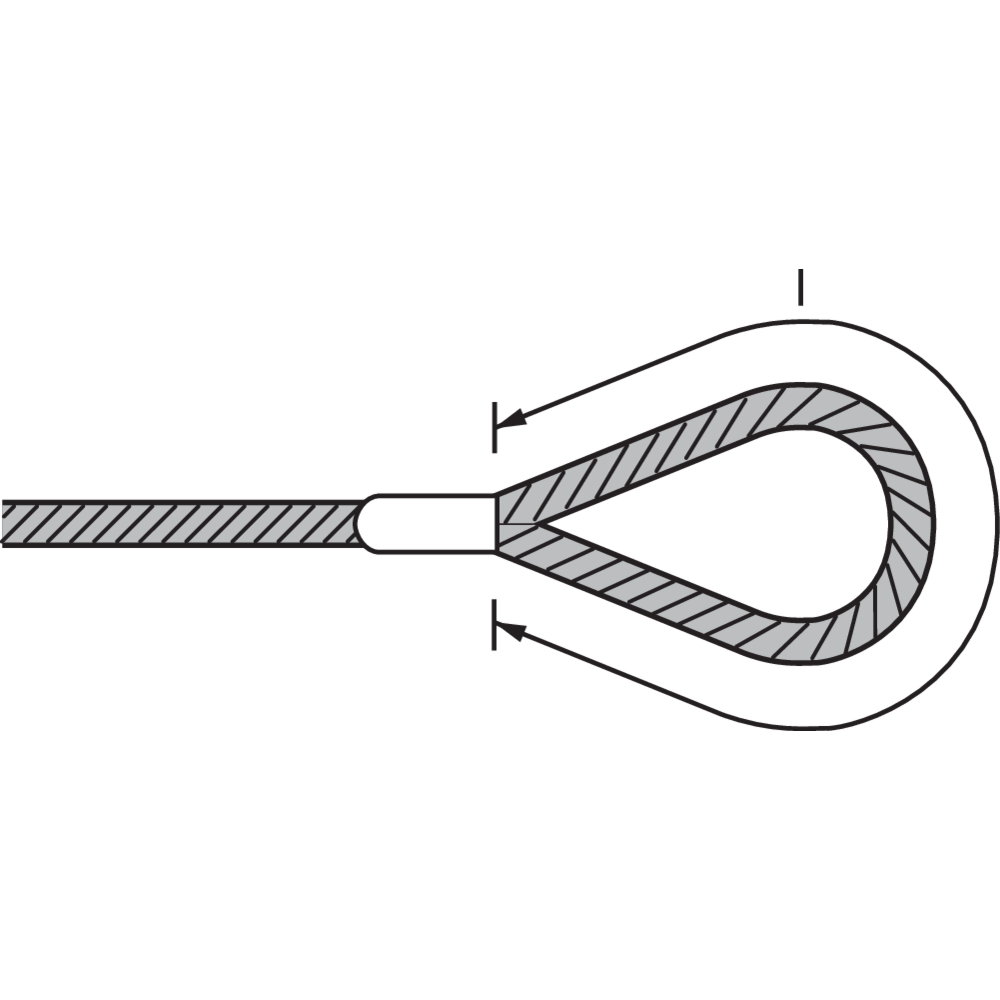

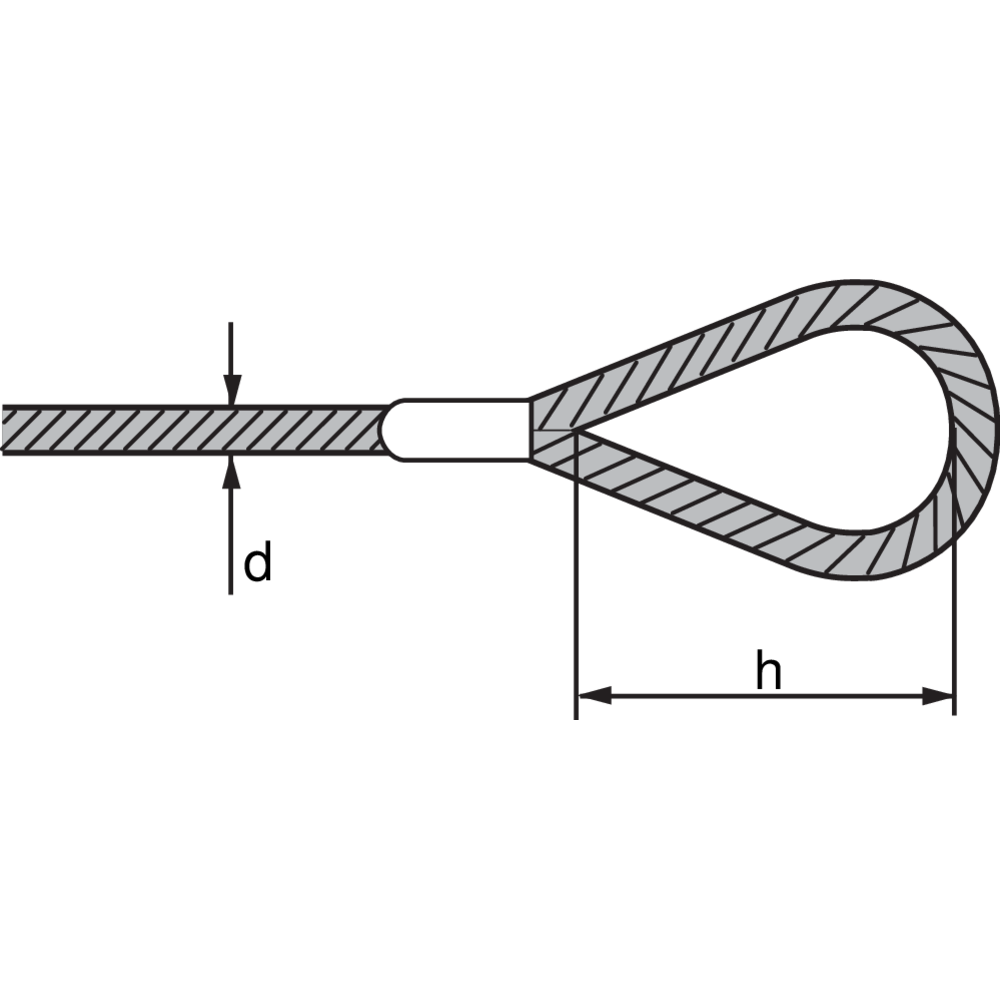

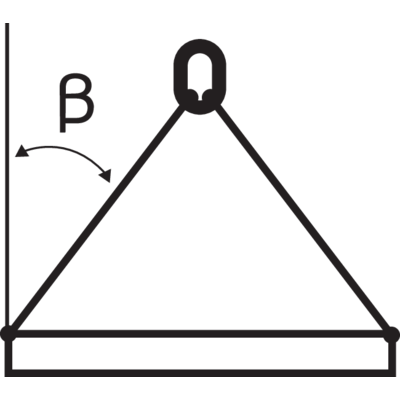

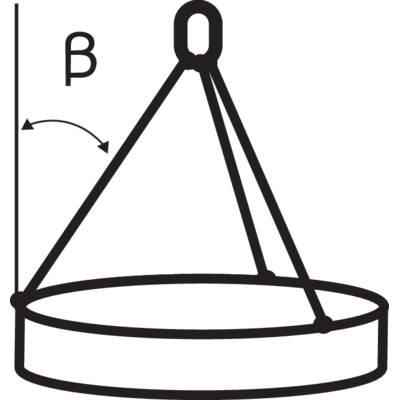

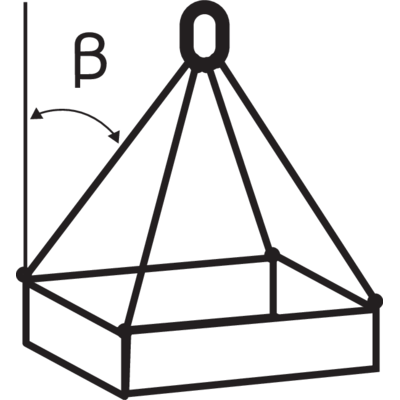

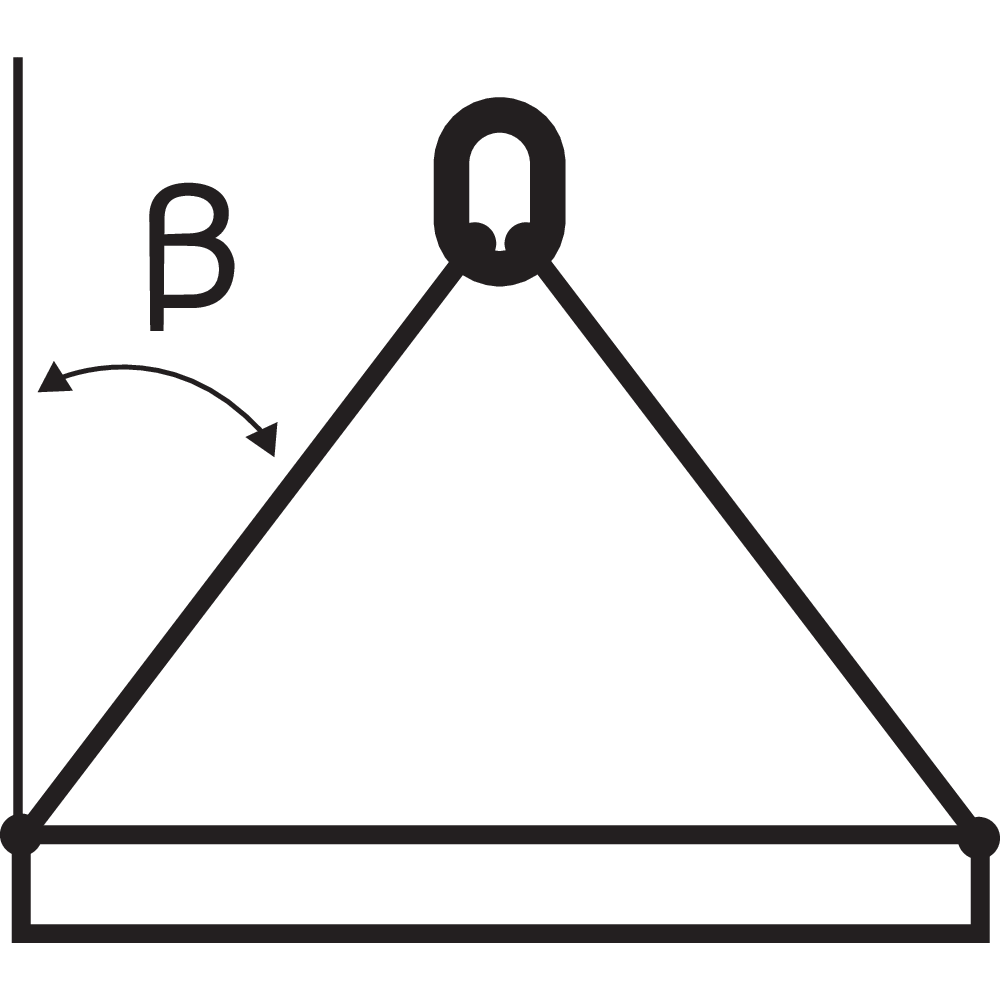

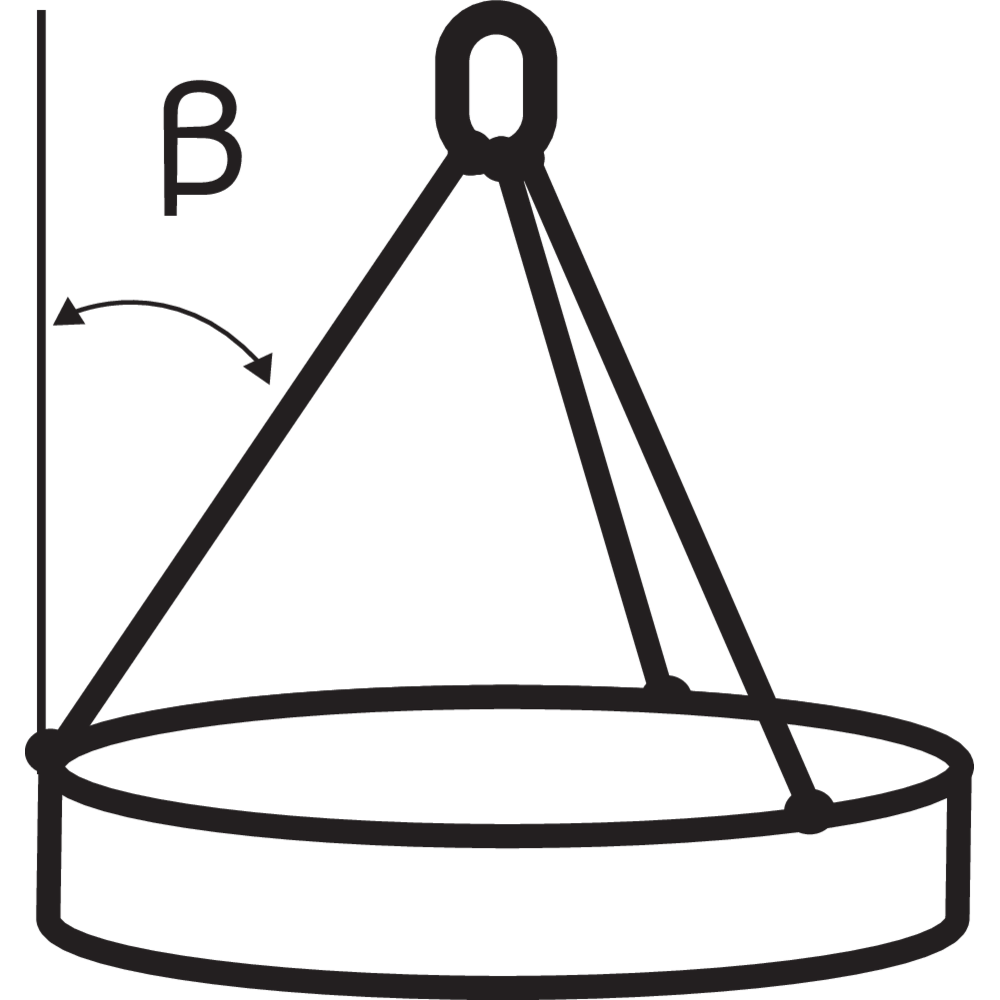

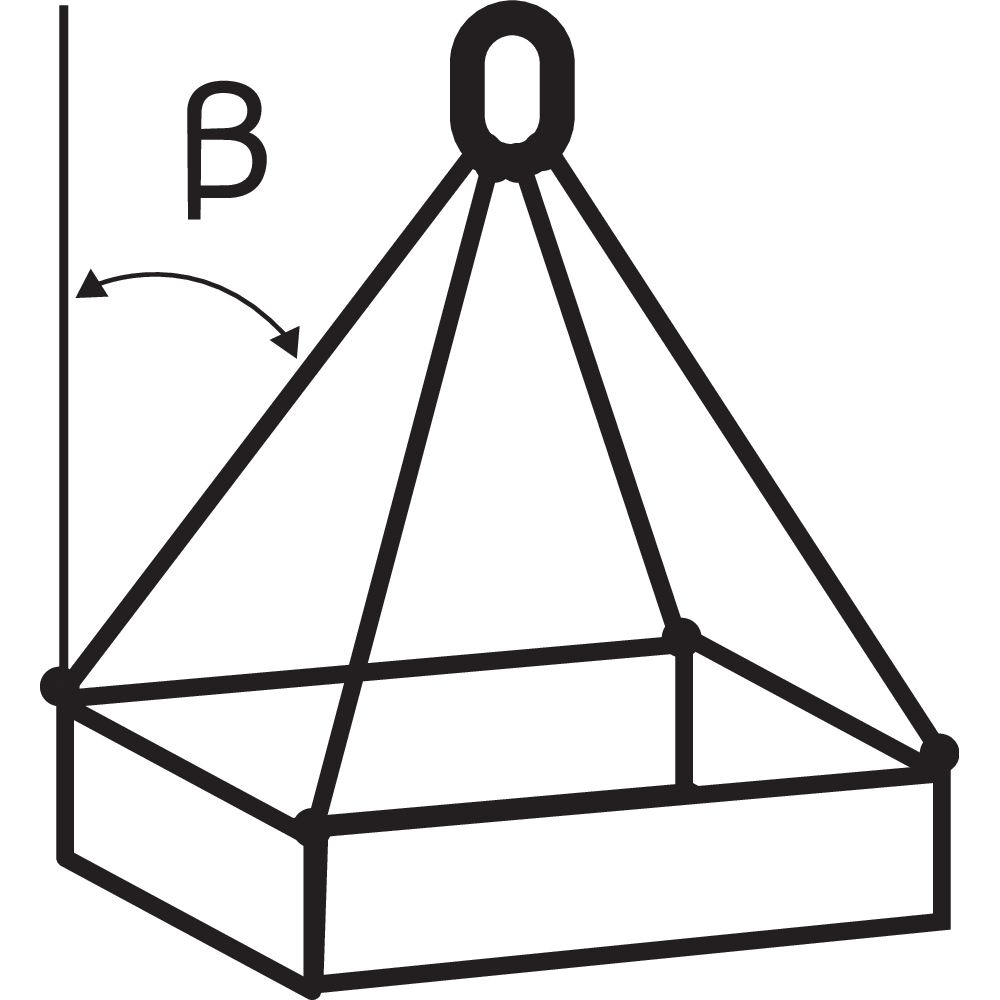

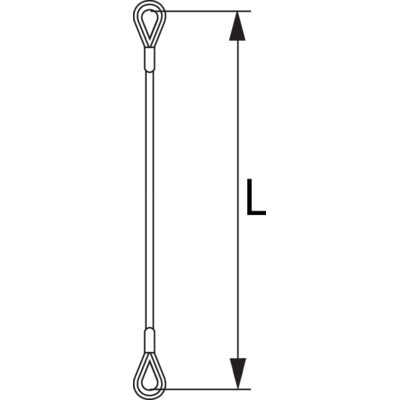

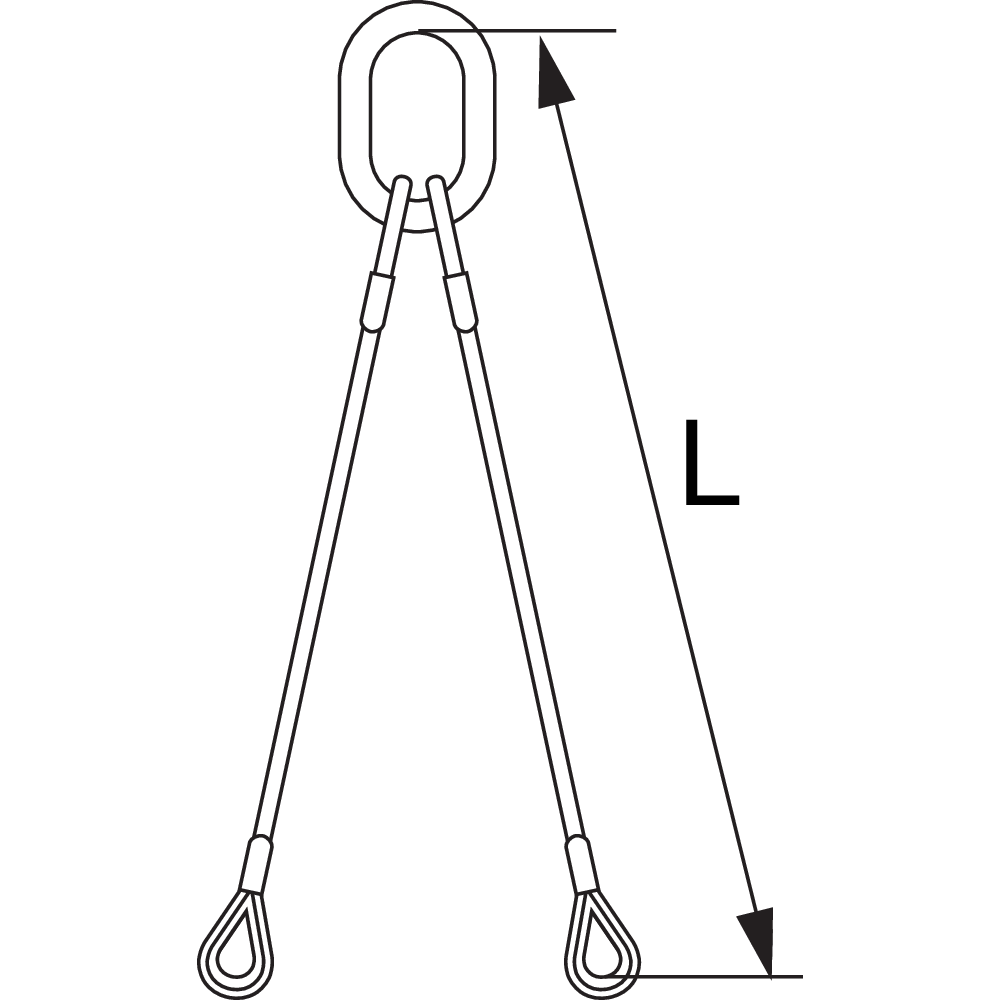

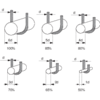

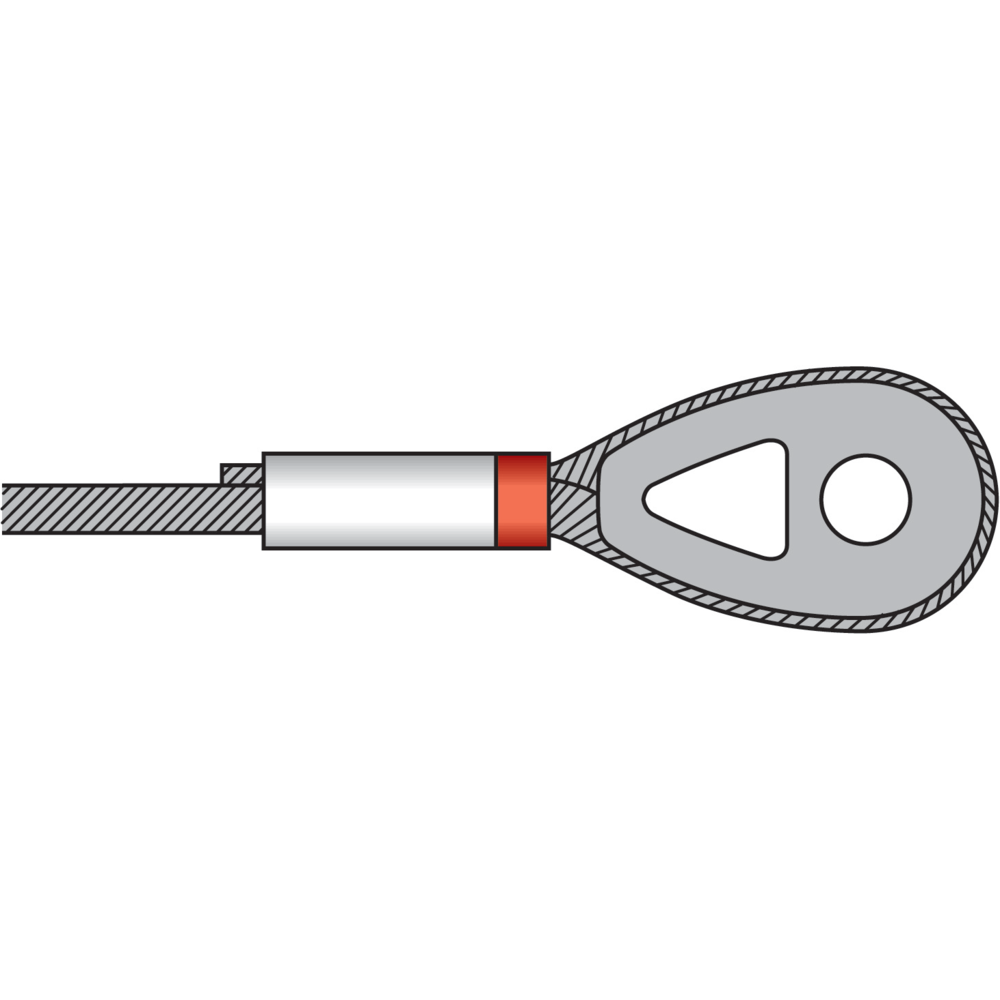

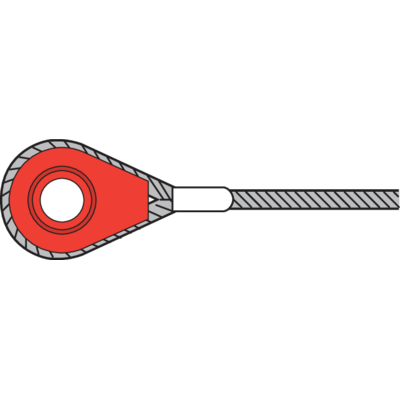

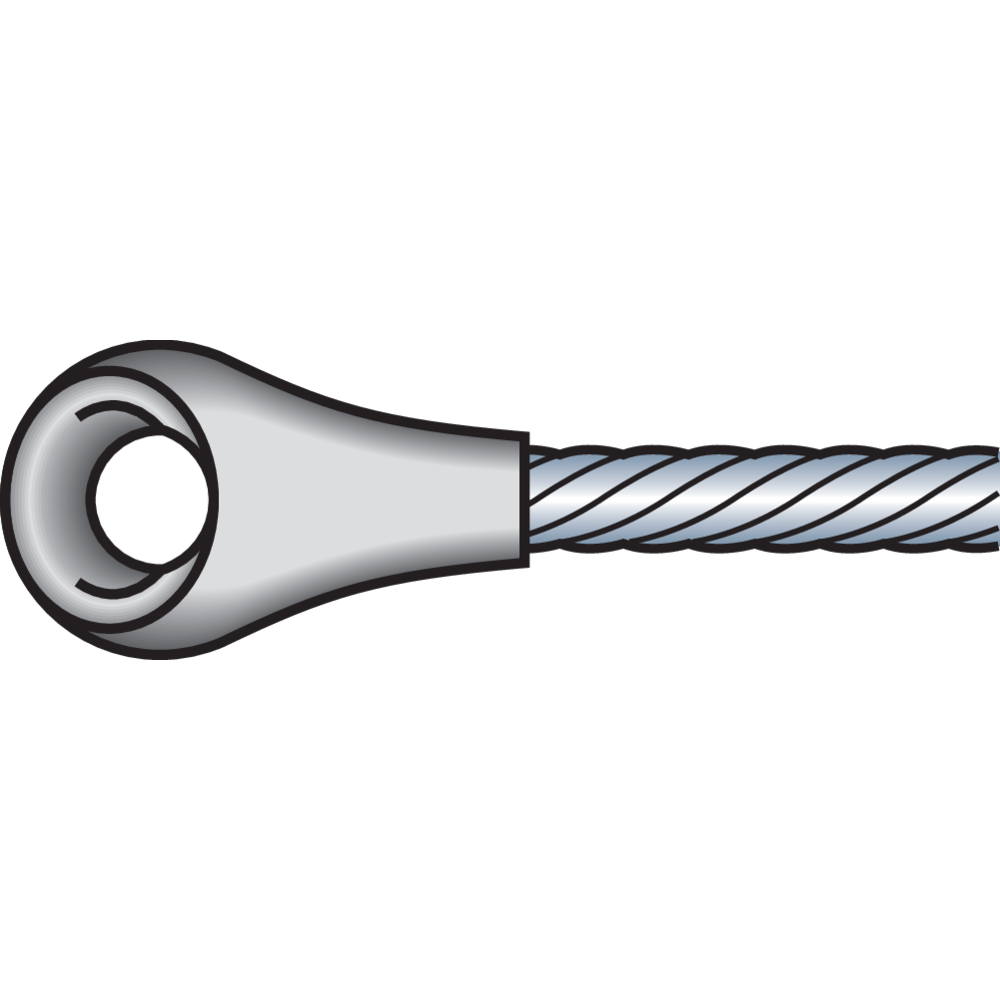

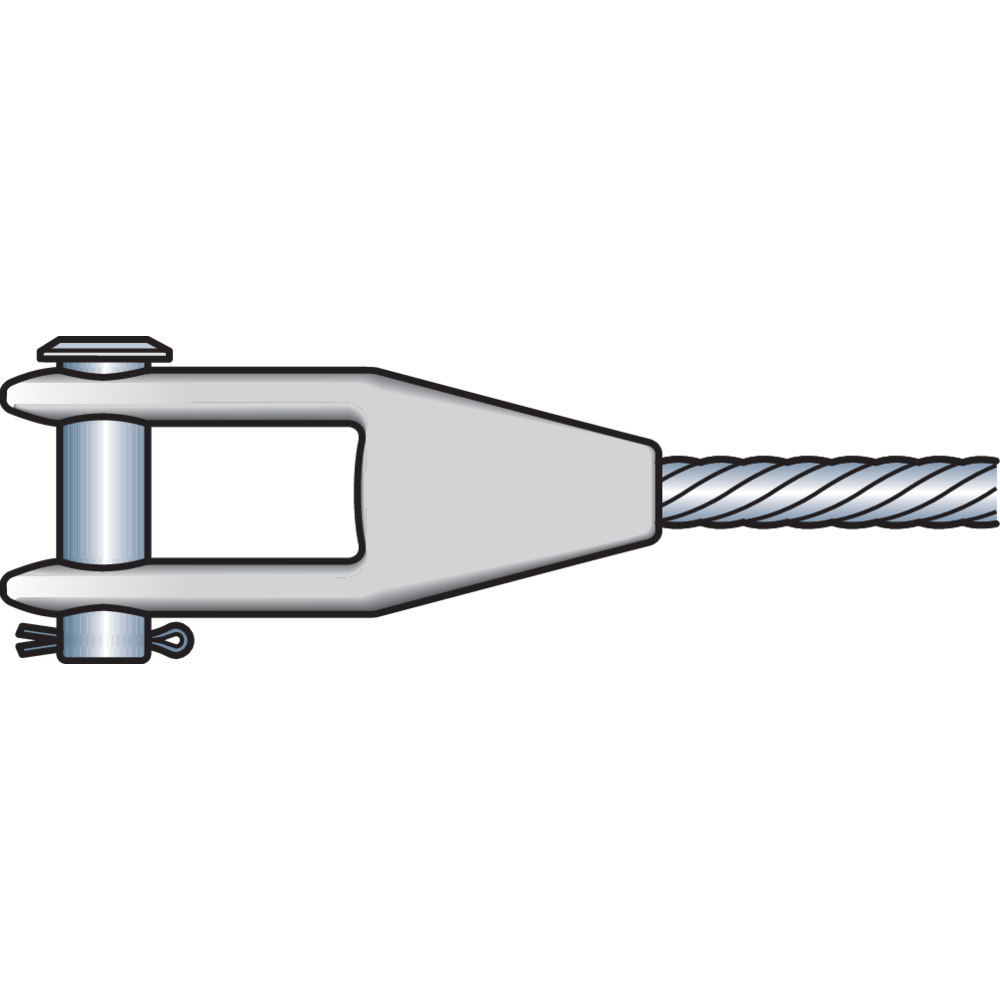

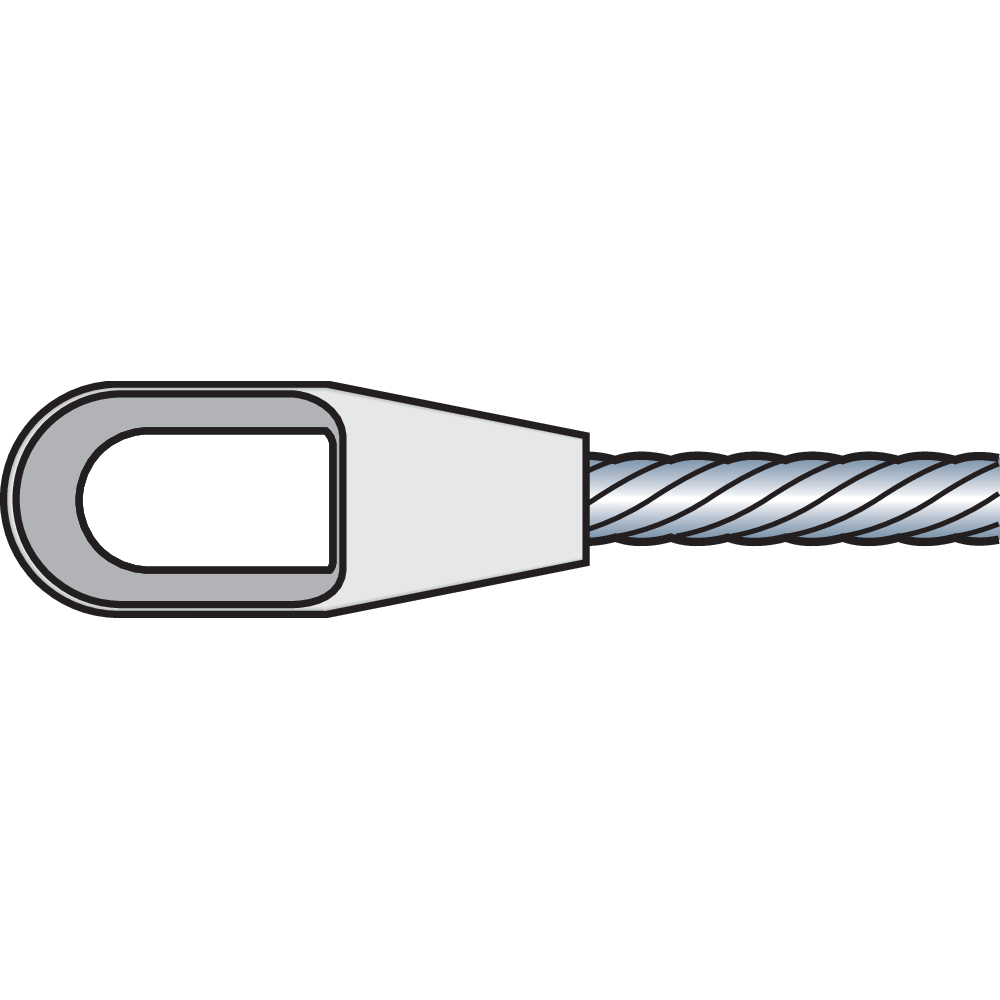

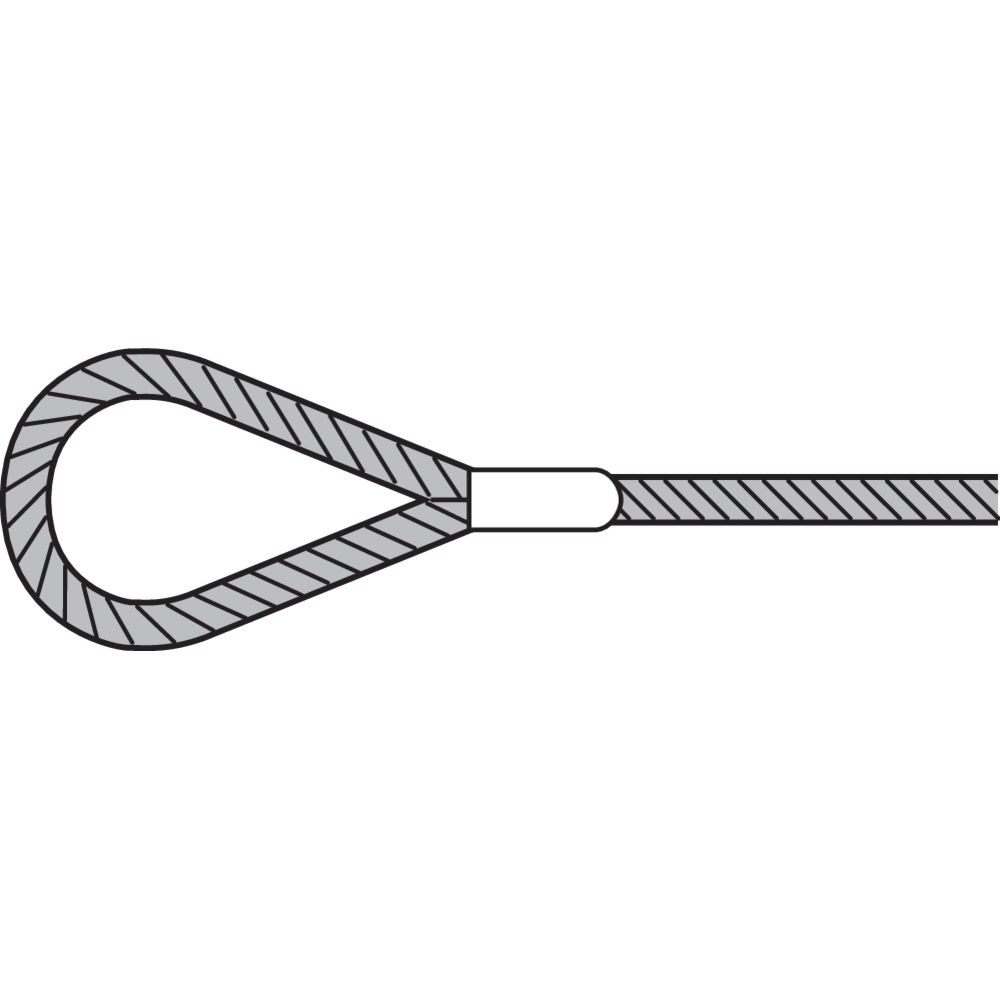

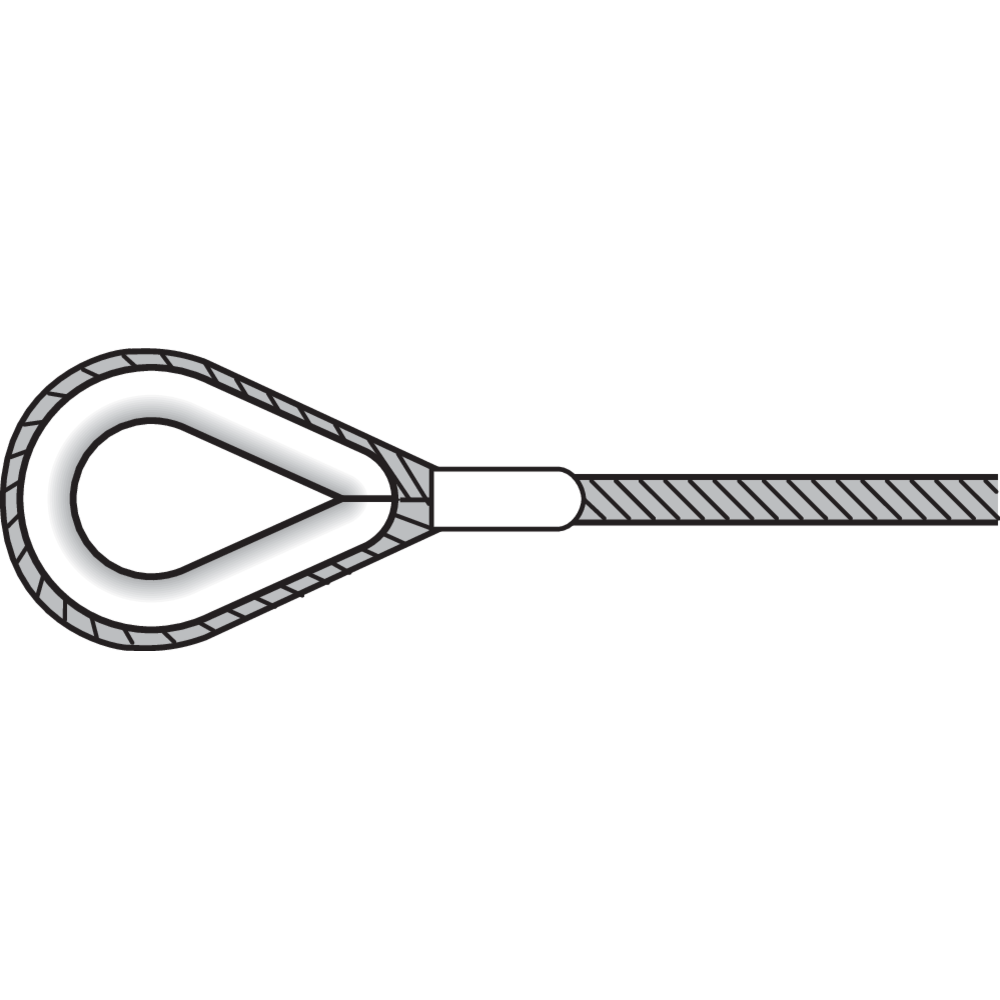

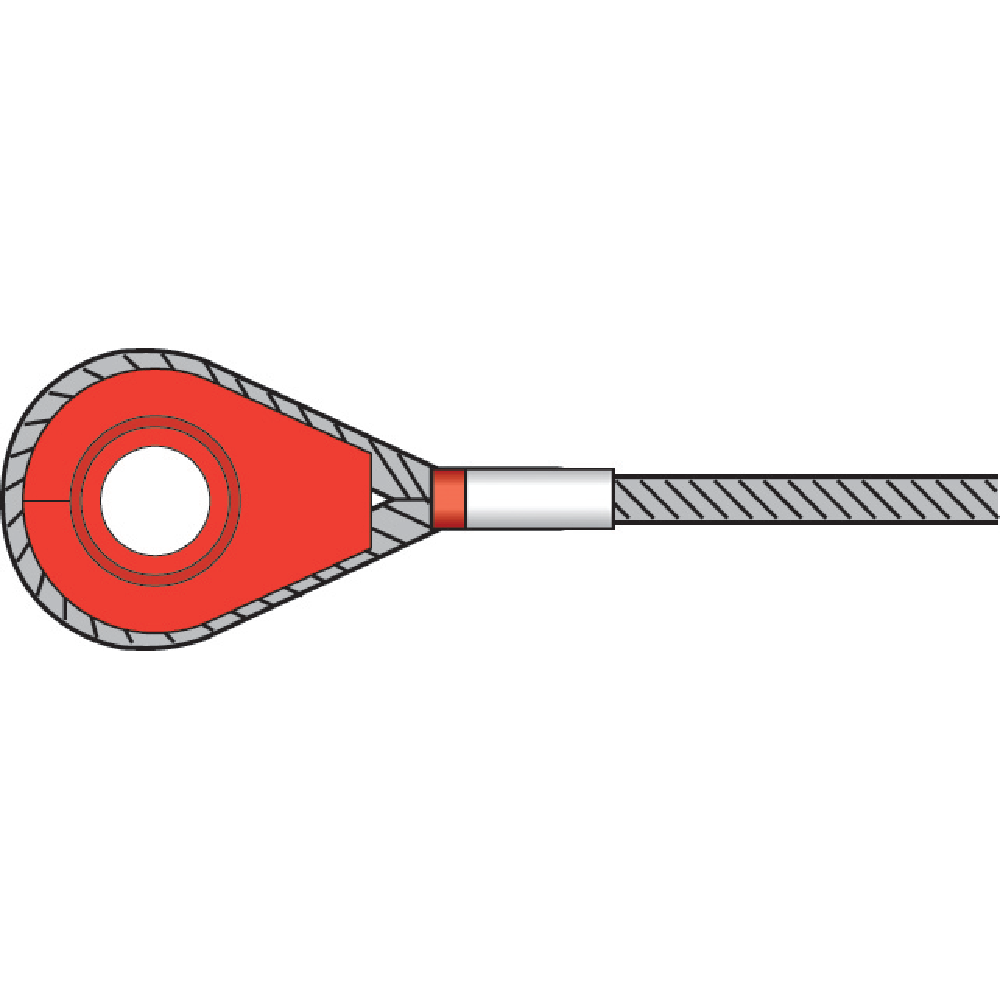

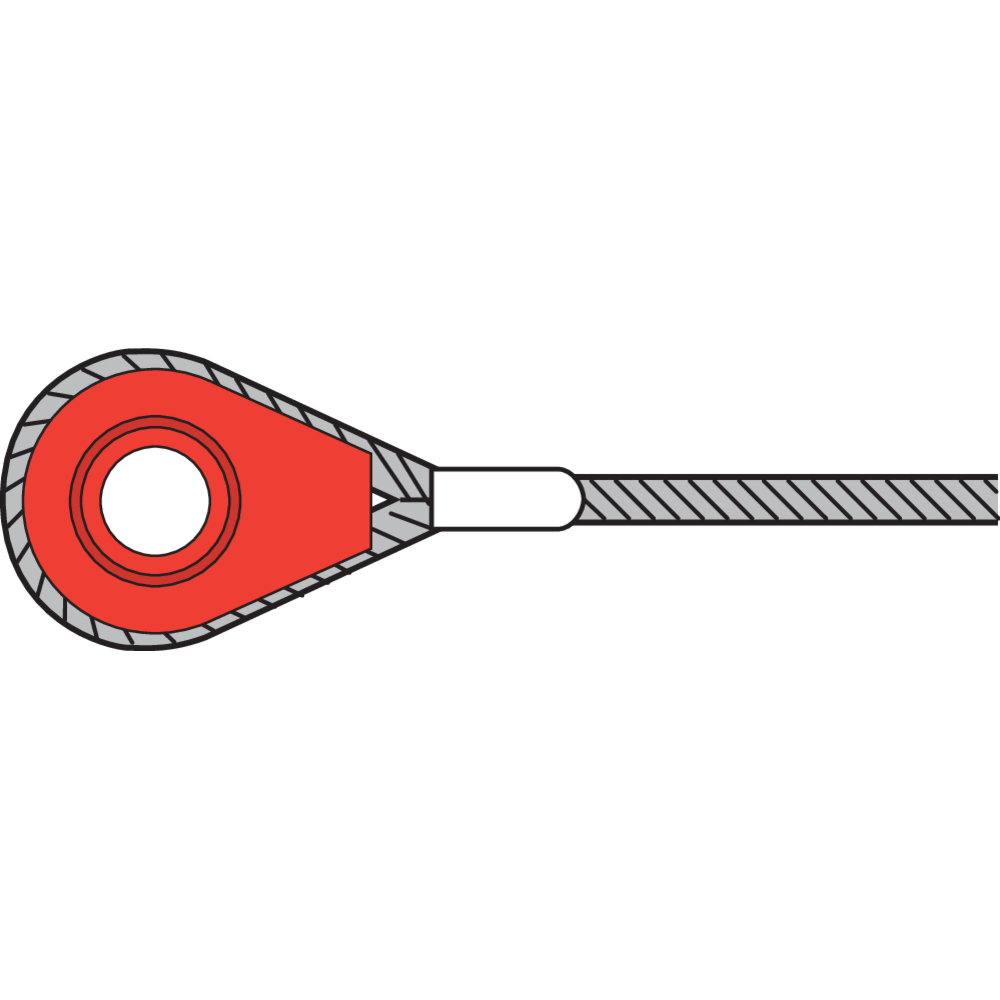

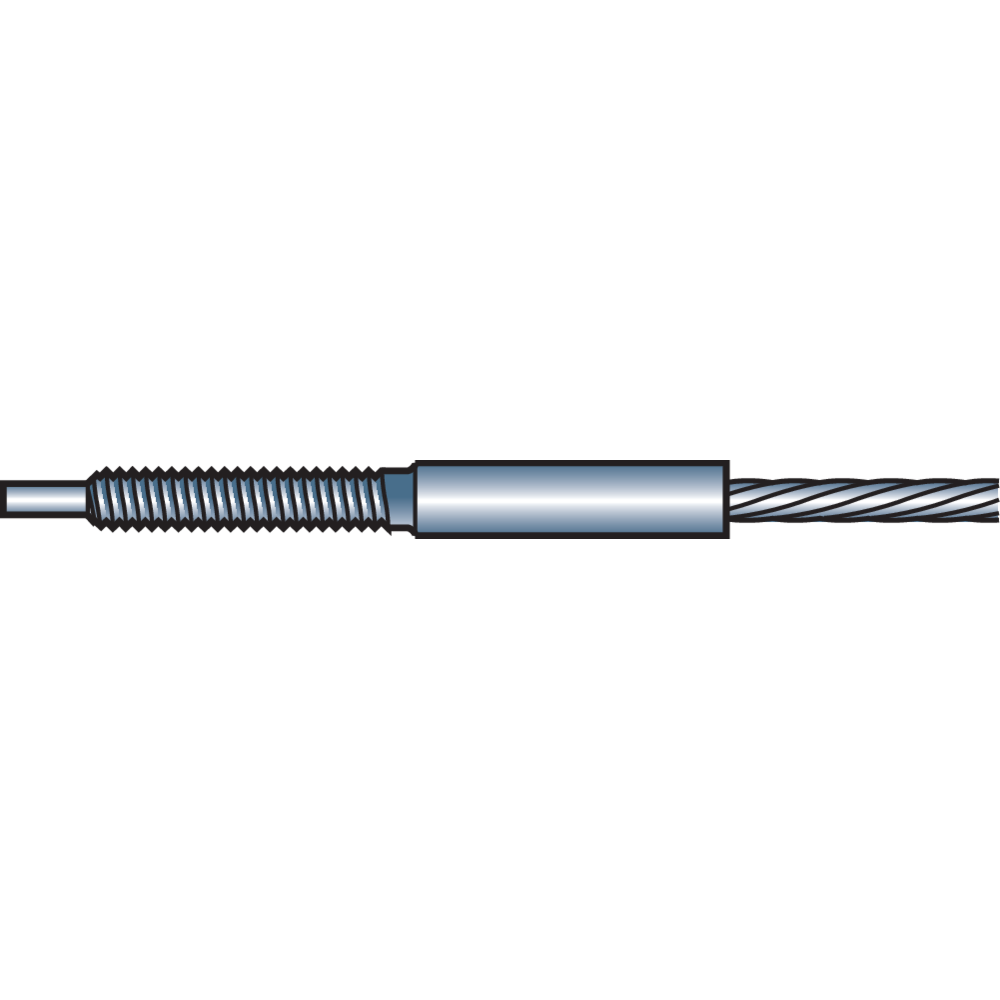

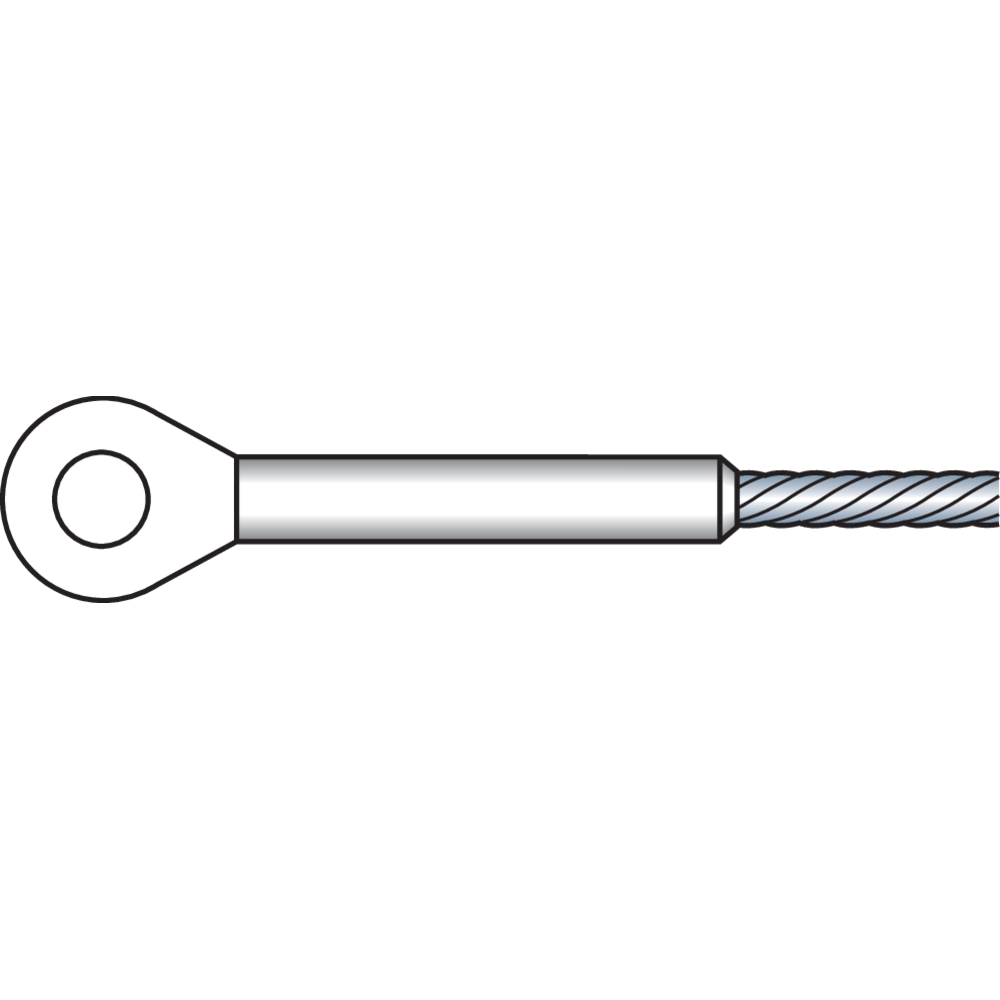

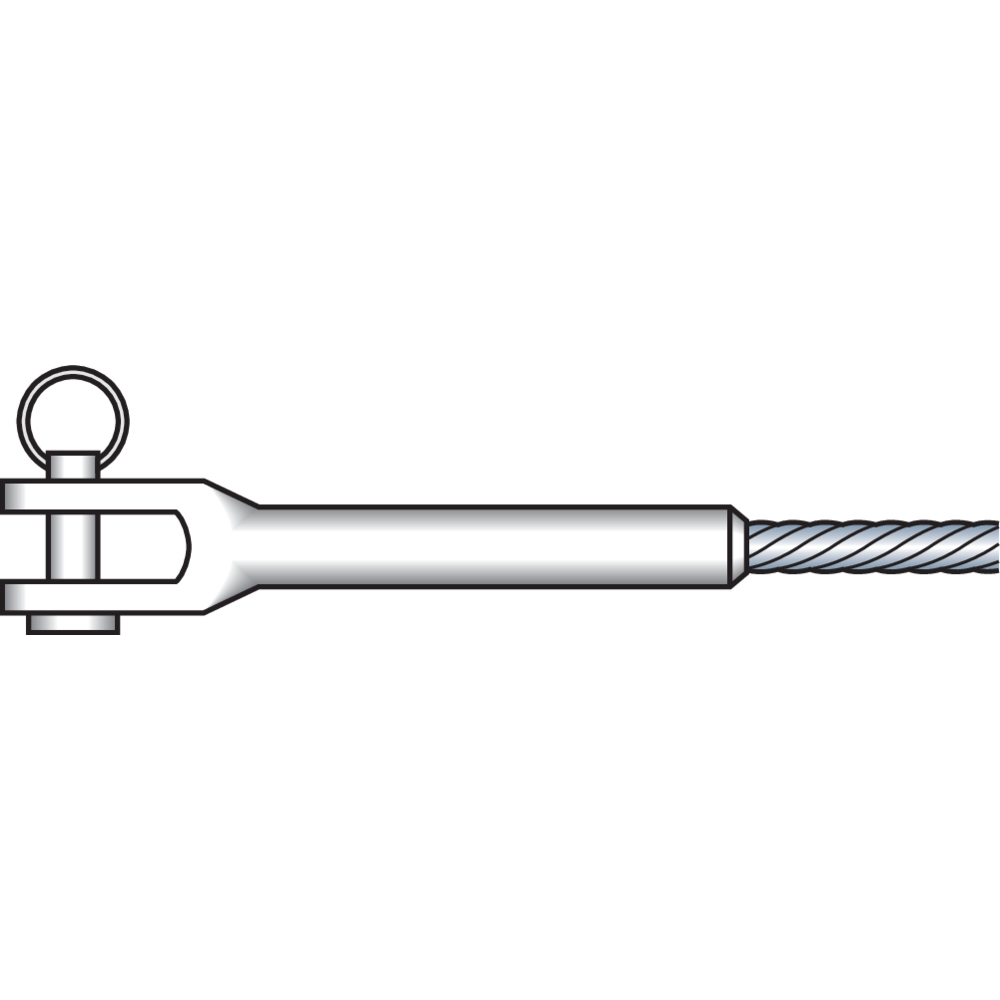

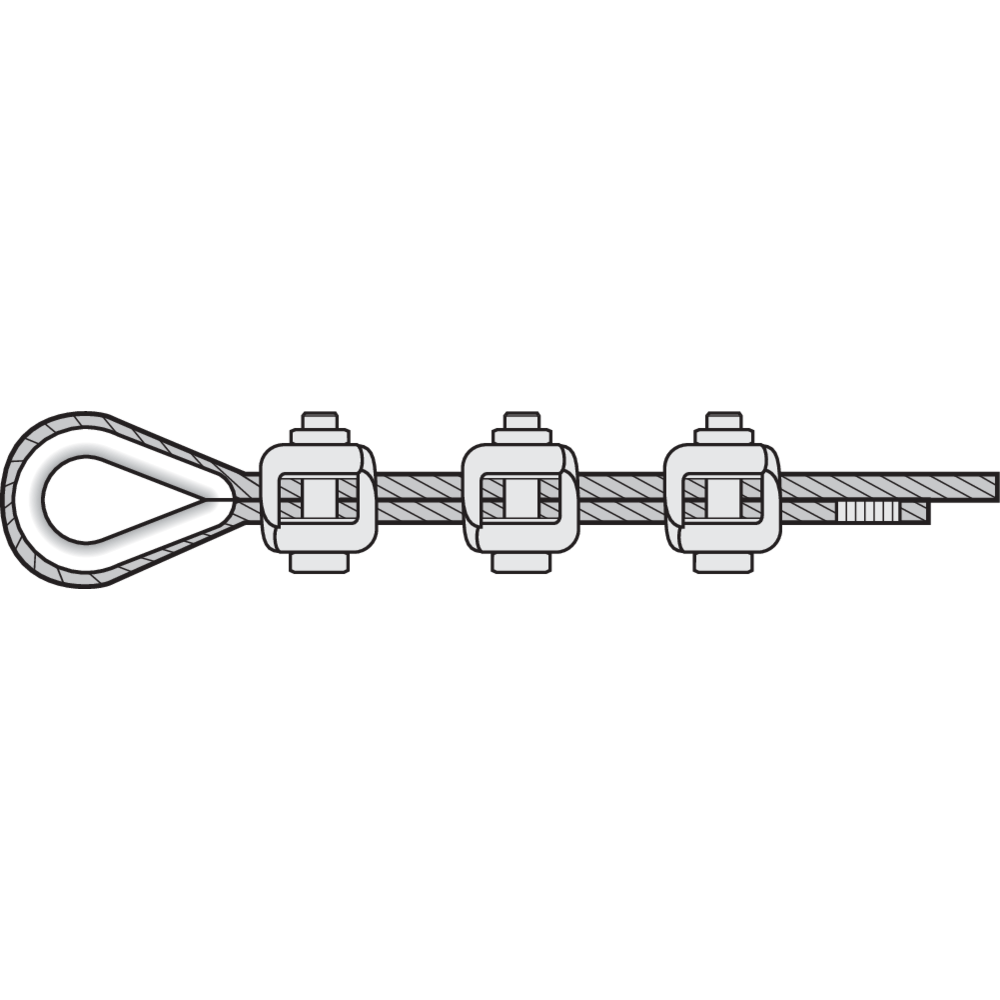

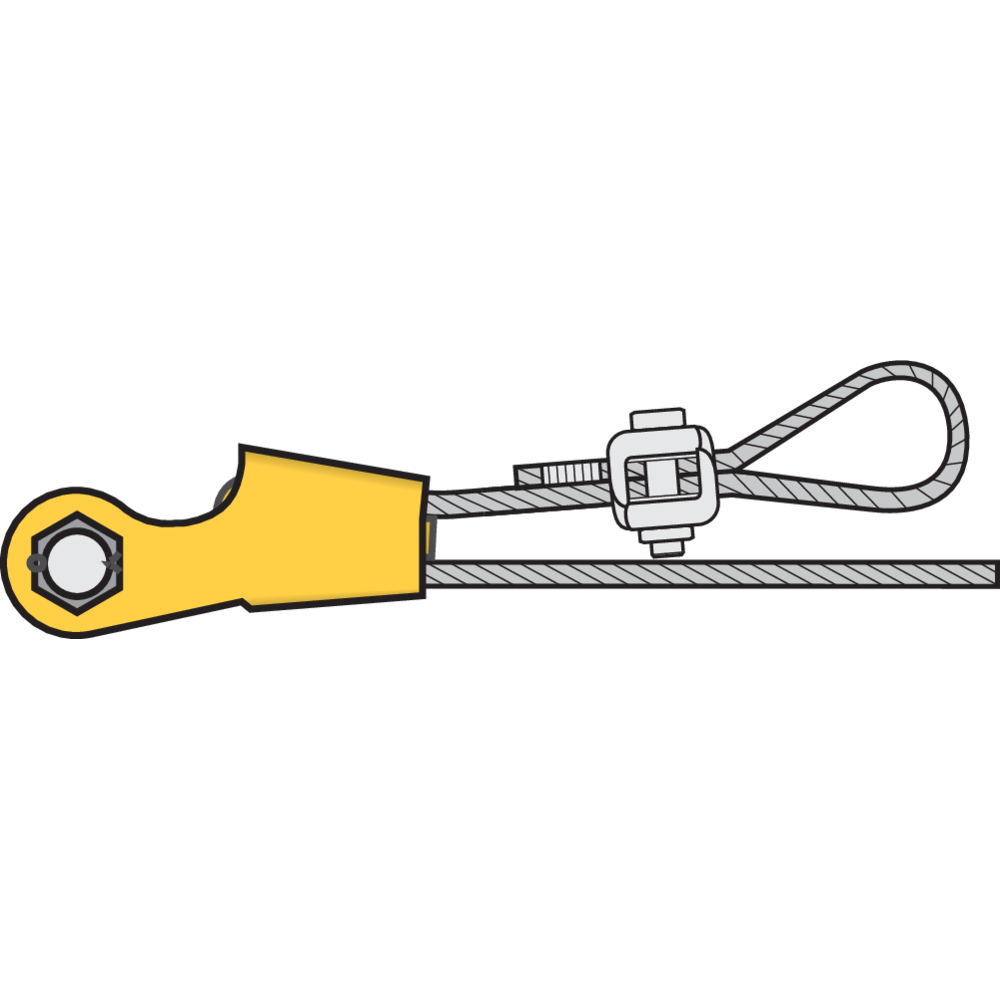

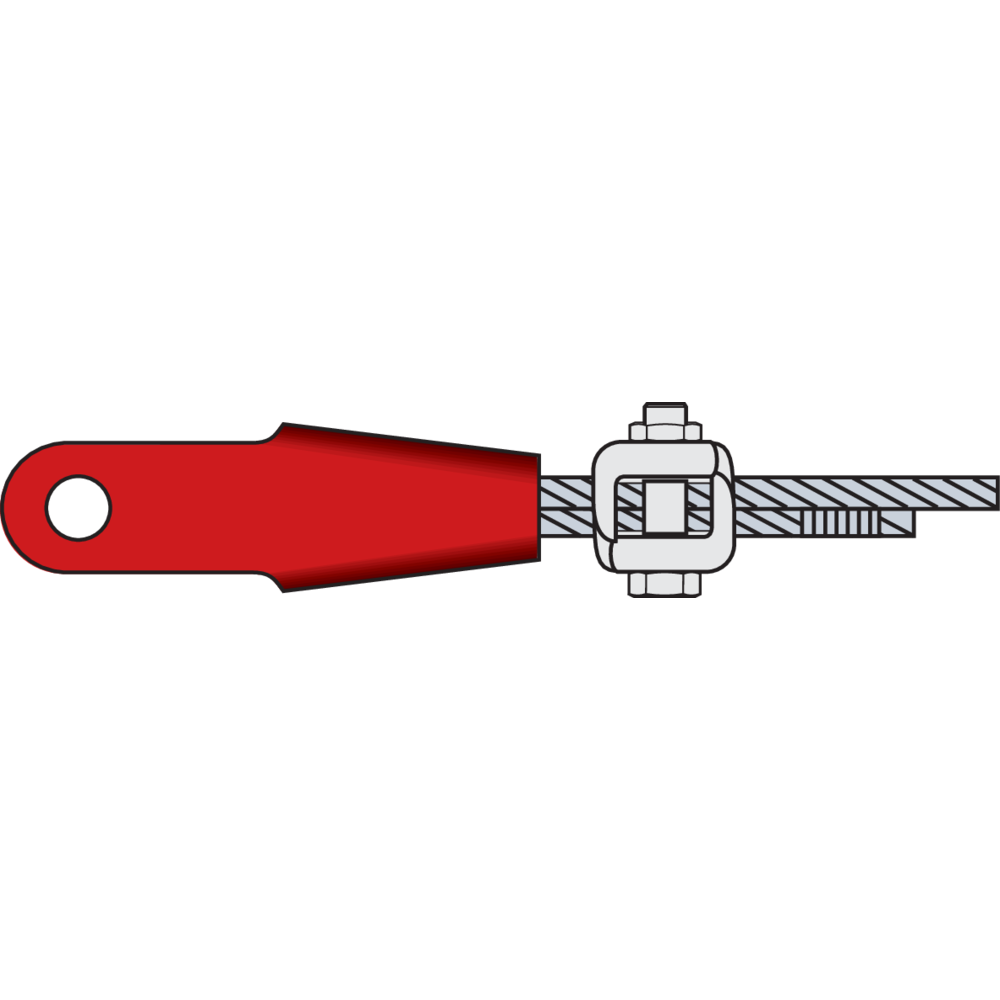

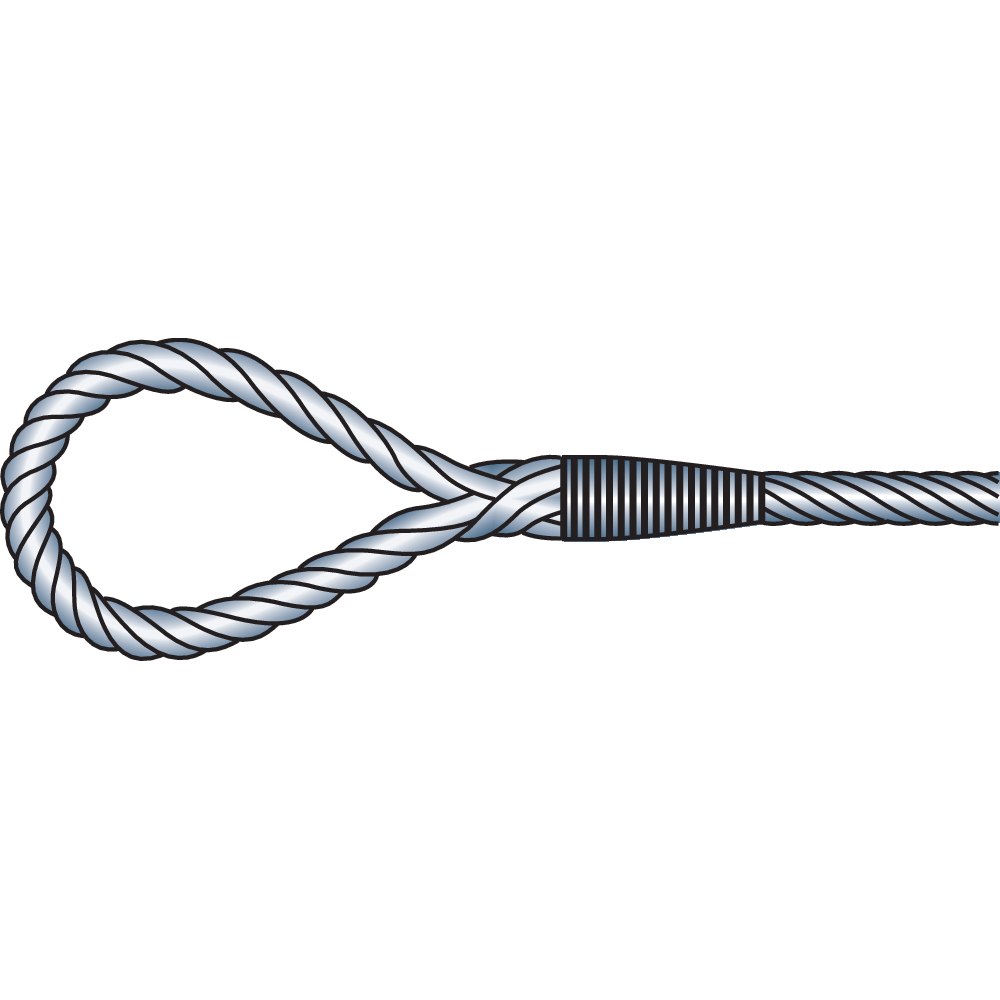

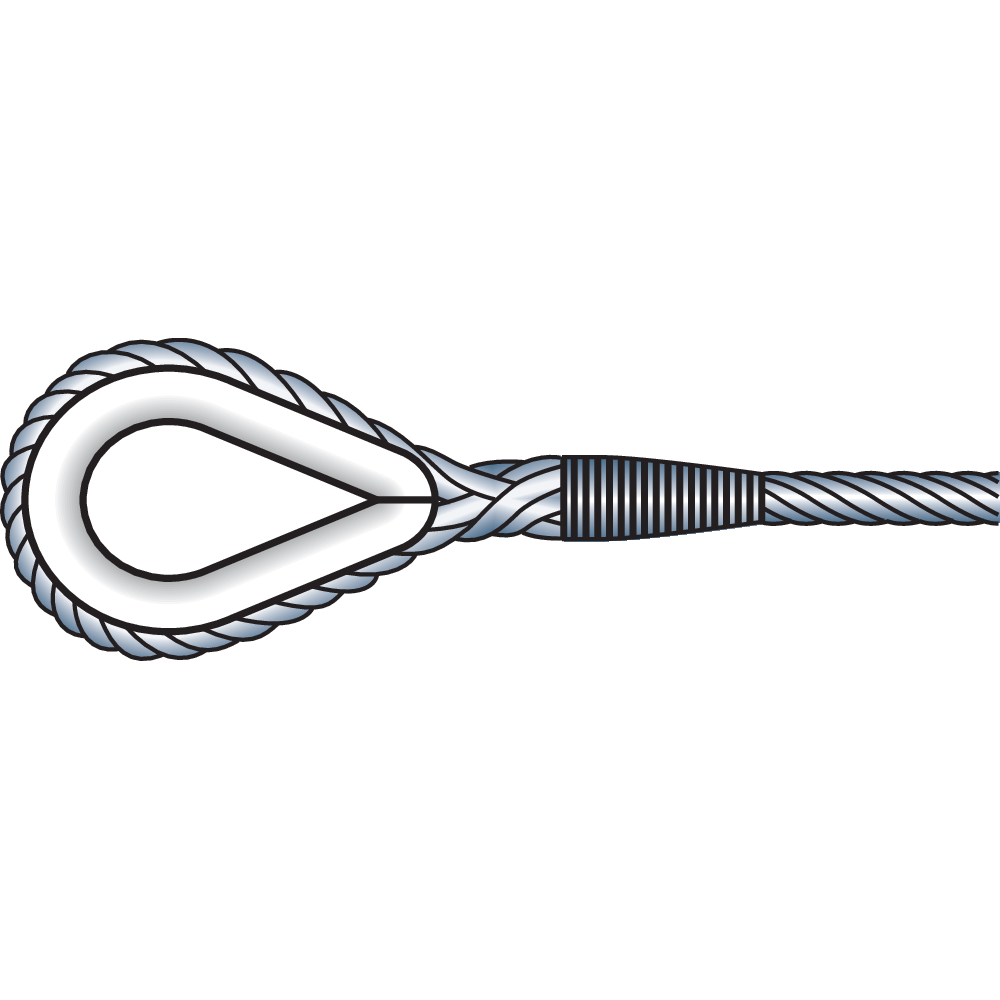

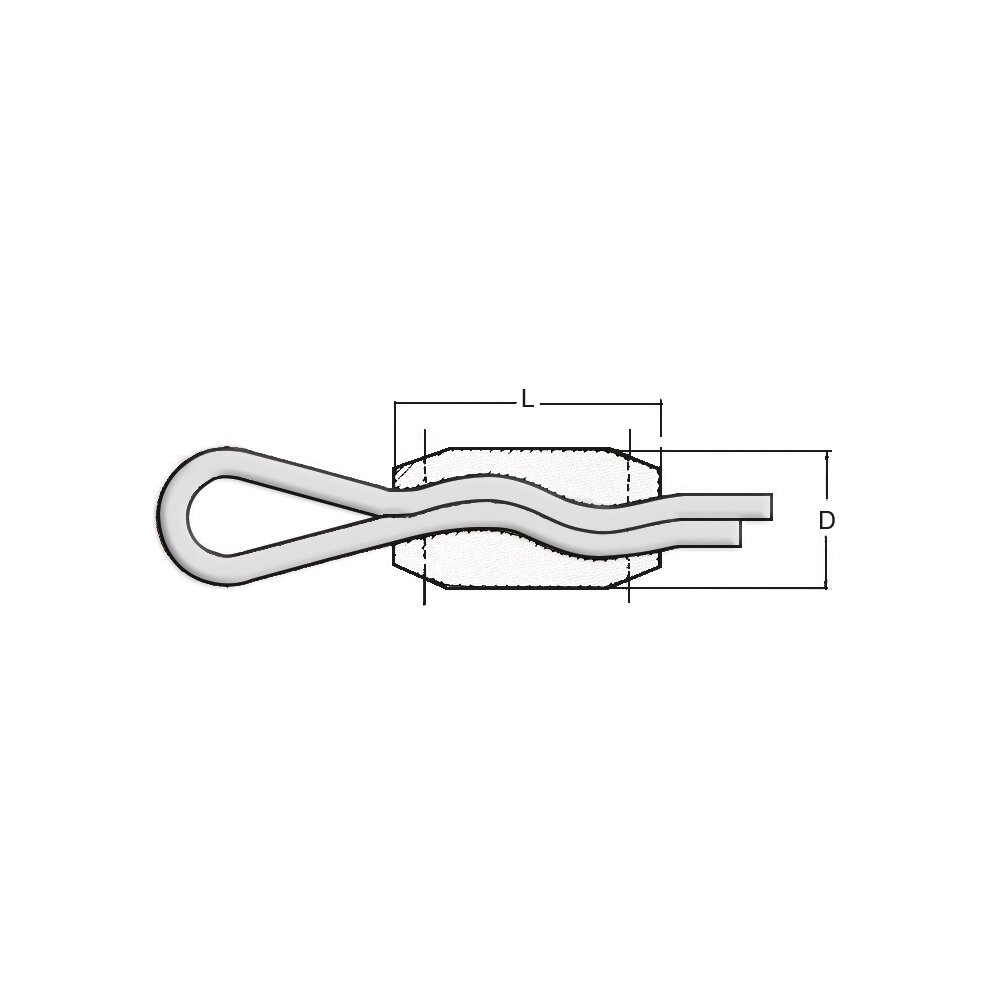

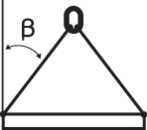

Material/Design: For manufacturing of wire rope slings the rope grade shall be either 1770 or 1960 N/mm². In multi-leg slings the rope dimension and grade shall be the same for each leg. The working load limit of the lower terminal fitting(s) shall be at least equal to that of the leg(s) to which it is/they are fitted. Where a terminal fitting is used, the eye termination shall always be fitted with a thimble. For 3- and 4-leg slings a master link with intermediate link should bee used.

Safety factor: 5:1.

Standard: EN 13414-1

Note: EN 13414-1 is valid for diameter ø8 mm to ø60 mm