General:

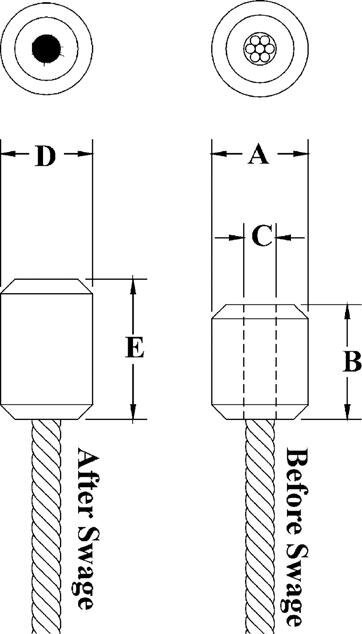

- Swage button terminations have an efficiency rating of 98% based on the catalog strength of wire rope.

- Special processed, low carbon steel.

- COLD TUFF for better swageability.

- Stamp for identification after swaging without concern for fractures (as per directions in the wire rope end terminations user's manual).

- Note: Length is measured from outside end of termination.