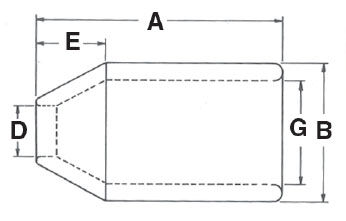

- For flemish eye wire rope splicing.

- Designed for low temperature toughness.

- Resists cracking when swaged (equals or exceeds stainless steel sleeves).

- Special processed low carbon steel.

- COLD TUFF® for better swageability.

- Can be stamped for identification after swaging without concern for fractures when following these directions.

- Use round corner stamps to a maximum depth of 1.38mm.

- The area for stamping should be on the side of the sleeve in the plane of the sling eye, and no less than 7mm from either end of the sleeve.

- Standard Steel Sleeve terminations have efficiency ratings as follows based on the catalog strength of wire rope.

After click on the “Show table” button, you will see the table with all technical details about the product.