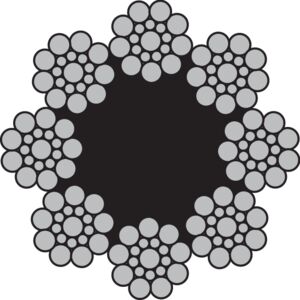

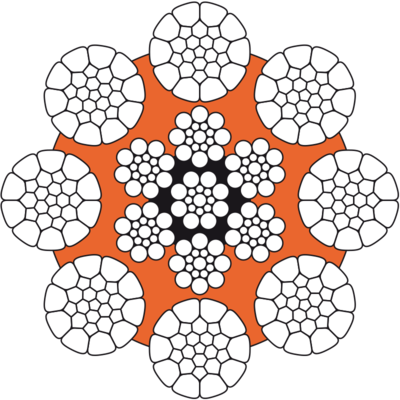

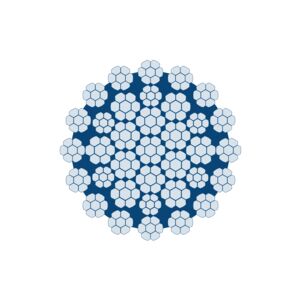

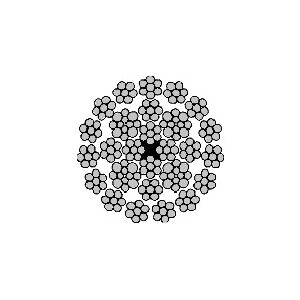

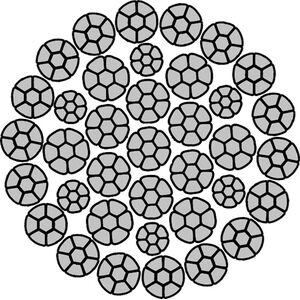

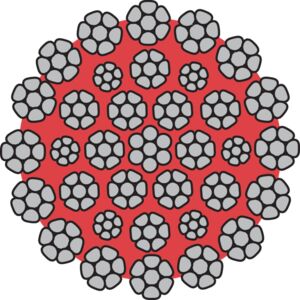

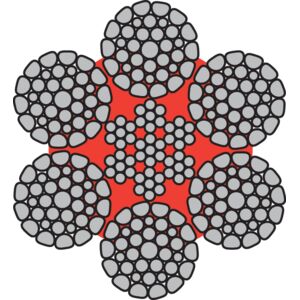

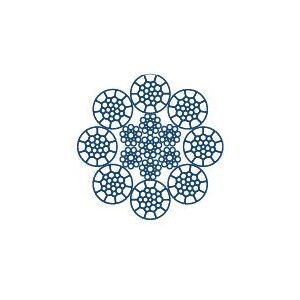

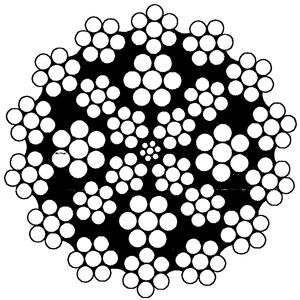

Wire rope construction: veropro 8 is a 8-strand, non rotation-resistant rope with compacted outer strands and a rope core covered with a plastic layer.

Features:

- Very high breaking strength.

- Very stabile rope construction with very good fatigue properties.

- A plastic layer between inner and outer strands prevents inner wear and protects the core from corrosion.

- Very high resistance against flattening and wear.

- Specially suitable for multilayer spooling (Lang Lay).

ISO 4309

Rope Category No: Up to 42mm RCN.09, 43-48mm RCN.11, > 48mm RCN.13

- Marking: According to standard

- Standard: EN 12385-4

- Warning: veropro 8 may not be used with a swivel.

- Fill factor: 0.666

- RCN: 09

- Tolerance Ø: +2% to +4%

Steel wire rope Veropro 8

Steel wire rope Veropro 8

Steel wire rope Veropro 8

Steel wire rope Veropro 8

![Dyform 6[new]_225mm](/pim/assortment/Steel%20wire%20ropes/Other%20Crane%20Rope/1518/image-thumb__1518__product-small/dyform-6-new-_225mm.8f93cf39.jpg)

![Trulift 6F[new]](/pim/assortment/Steel%20wire%20ropes/Elevator%20Rope/1427/image-thumb__1427__product-small/trulift-6f-new-_225mm.17c47bf2.jpg)