Features:

- Swage sockets incorporate a reduced machined area of the shank which is the equivalent to the proper after swage dimension. Before swaging, this provides for an obvious visual difference in the shank diameter. After swaging, a uniform shank diameter is created allowing for a QUIC CHECK™ permanent visual inspection opportunity.

- Designed to quickly determine whether the socket has been through the swaging operation and assist in field inspections, it does not eliminate the need to perform standard production inspections which include gauging for the proper after swage dimensions or proof loading.

- Hardness controlled by spheroidise annealing.

- Swage socket terminations have an efficiency rating of 100% based on the catalogue strength of wire rope.

- Material: Carbon Steel.

- Marking: ID code and Manufacturer's symbol.

- Finish: Ungalvanised.

- Safety factor: 5:1

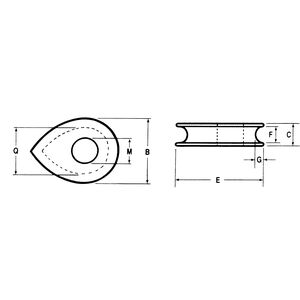

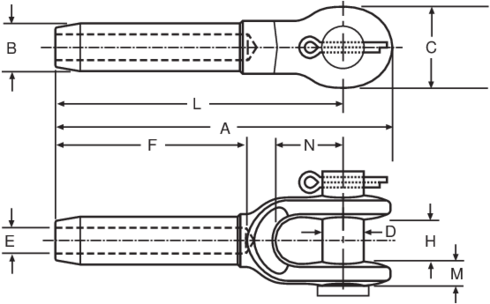

Open Swage Socket Crosby S-501

Open Swage Socket Crosby S-501

Open Swage Socket Crosby S-501

Open Swage Socket Crosby S-501